Wir sorgen für beste Performance

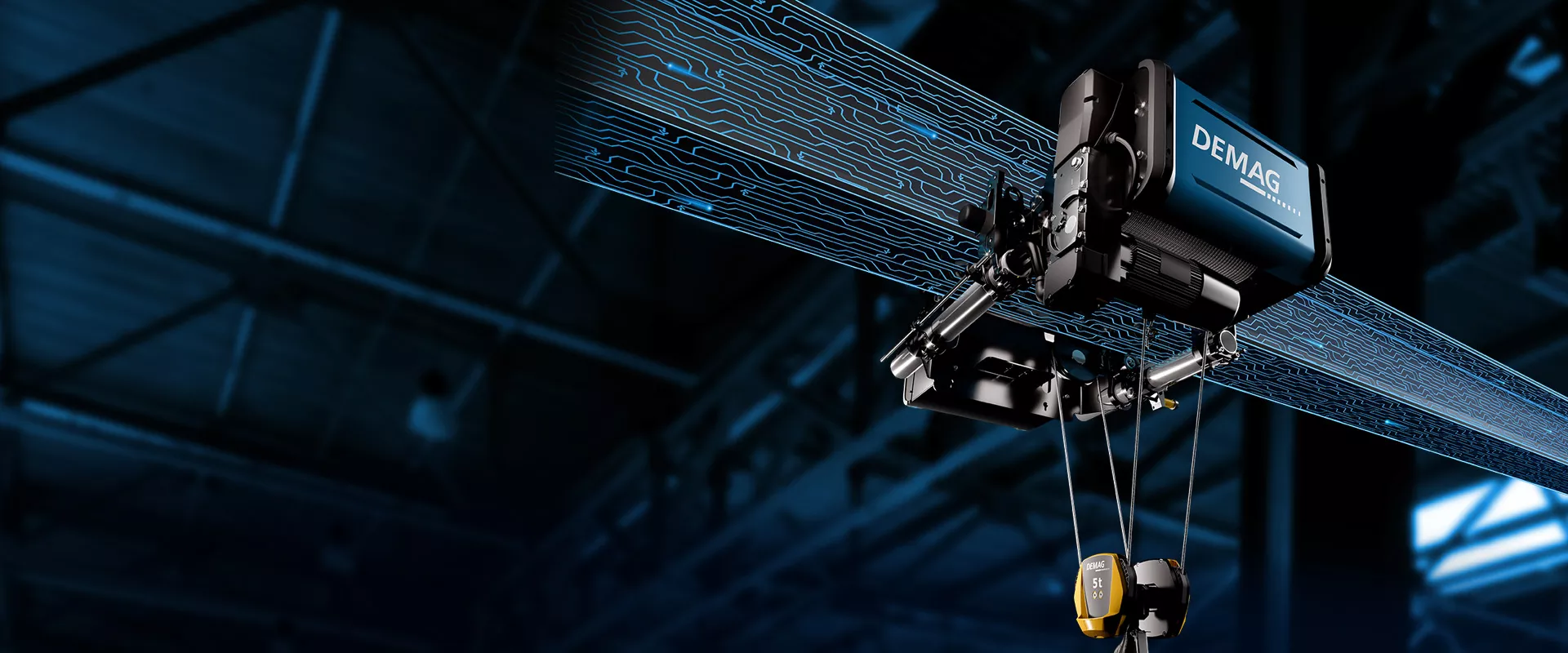

Leistungsstarke und zuverlässige Leichtkransysteme, Krankomponenten und Antriebstechnik: das ist unsere Kernkompetenz. Als einer der weltweit führenden Hersteller bieten wir unseren Kunden seit mehr als 200 Jahren ein umfassendes Portfolio an Lösungen für Materialfluss und Logistik – und ermöglichen ihnen so höchste Wirtschaftlichkeit und beste Performance.

Entdecken Sie die Welt von Demag!

Ihr persönlicher Kontakt

Unser Partnernetzwerk und die Demag Spezialisten bieten Ihnen technische Kompetenz vor Ort rund um unsere Produkte und den dazugehörigen Service. Sie stehen Ihnen mit ihrem Know-how zur Verfügung und sorgen für eine schnelle Unterstützung bei offenen Fragen sowie für eine aktive Unterstützung Ihrer Projekte.

Sie brauchen Beratung zu:

- Krane

- Leichtkransysteme und Hebezeuge

- Antriebstechnik

- Service

Wir sind immer an neuen Aufgaben interessiert! Unsere Referenzen zeigen Anwendungen mit denen wir unseren Kunden geholfen haben, ihre Ziele zu erreichen.